What Is Rabitz? (A Professional Buying Guide Based on Weight, Ribs, and Mesh Size)

Rabitz is an expanded metal mesh produced by cutting and stretching galvanized steel sheets. The purpose of this mesh is to create a suitable base for the adhesion of plaster, cement mortar, or similar compounds, especially when the substrate lacks sufficient strength or when special shaping such as curves, arches, domes, and decorative ceilings is required. The regular mesh structure of rabitz allows mortar loads to be distributed more evenly, resulting in a stronger final surface. For this reason, this product holds a very important position in construction projects, both in substructure work and finishing stages.

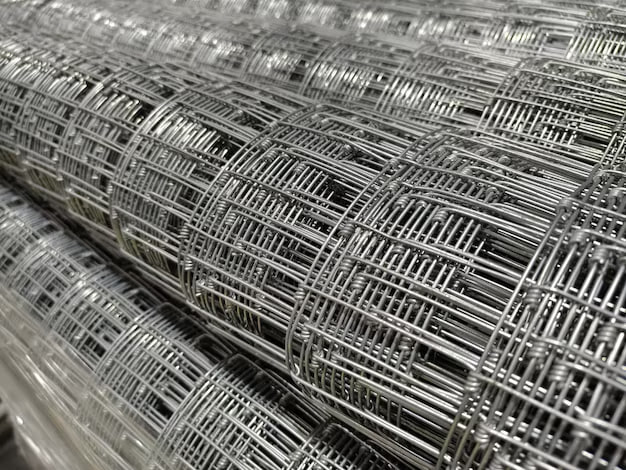

What Material Is Rabitz Made Of?

The primary material of rabitz is steel sheet, which becomes resistant to moisture through galvanizing processes (hot-dip or electro-galvanized). In practice, black steel sheet is first coated with a zinc layer to form galvanized sheet, then enters the punching and stretching stage to create the mesh structure of rabitz. This galvanized coating is extremely important because rabitz is usually in direct contact with plaster and moist mortars, and resistance to corrosion is one of the most critical selection criteria.

The standard dimensions of a rabitz sheet are typically 240 cm in length and 60 cm in width, covering approximately 1.44 square meters. This standardization allows engineers and contractors to easily calculate material consumption for each project.

Key Factors in Rabitz Classification and Purchasing

In rabitz classification systems, three main factors play a decisive role: number of ribs (columns), sheet weight, and mesh size. Each of these parameters directly affects quality, application, and final price. Understanding them helps buyers make accurate choices and avoid common market mistakes.

Number of Ribs (Columns)

Ribs are the longitudinal lines that divide the rabitz sheet into regular sections. The number of ribs is the first indicator of mesh strength. Nine-rib rabitz is considered lightweight and economical and is typically used for interior plastering and simple ceilings. Eleven-rib rabitz provides a balance between weight and strength and is suitable for medium-scale projects. In contrast, thirteen-rib rabitz has the highest mesh density and is used in heavy façade substructures and areas subjected to higher dead loads. As the number of ribs increases, mesh stability also improves.

Rabitz Weight (The Most Important Pricing Factor)

The weight of each rabitz sheet on the market generally ranges from about 350 grams to 1300 grams. Higher weight indicates thicker base sheet and greater mesh strength. Contrary to common misconceptions among inexperienced buyers, rib count alone does not determine quality; weight is a far more critical factor. For example, two thirteen-rib rabitz sheets may exist in the market, but one may be lighter and more flexible due to thinner material. In final decision-making, weight has a direct relationship with price and execution reliability.

Mesh Size

Meshes are the regularly repeated openings within the rabitz structure. Their size typically ranges from about 2×3 mm to 3×8 mm. Smaller mesh sizes perform better in fine plastering, interior ceilings, and areas requiring stronger mortar bonding. Larger mesh sizes are suitable for thicker cement layers or when higher adhesion strength is required. Therefore, selecting mesh size depends entirely on application type and mortar characteristics.

Main Applications of Rabitz in Construction Projects

Rabitz is one of the oldest yet most practical substructure materials in construction. Its use in suspended ceilings is very common, as it conceals installations and surface irregularities while allowing decorative designs. In façade works, rabitz plays a vital role by serving as a base for thick mortar layers and preventing detachment or cracking. It is also the preferred choice for arches, curves, and domes due to its high flexibility. Covering beams and columns and creating uniform surfaces for plaster and cement application are among its other main uses.

Rabitz Installation and the Importance of Binding Wire

Rabitz installation is always performed using binding wire, typically with diameters of 0.9 mm or 1.2 mm, to secure rabitz sheets to rebars or underlying metal structures. The galvanized type of this wire is particularly important because using black wire in contact with plaster and moisture can lead to corrosion, surface swelling, and plaster failure. Strong and uniform bindings ensure a smooth final surface without sagging or cracking.

Selection Guide and Factors Affecting Rabitz Price

Rabitz price is primarily determined by weight, followed by rib count and galvanized sheet thickness. For interior ceilings, lighter models with smaller mesh sizes are usually sufficient because high load resistance is not required. However, for heavy façades or areas with thick cement layers, heavier models (around 1200 grams with 13 ribs) are recommended to prevent detachment or failure. Proper selection minimizes rework costs and post-installation damage.

Comparative Table of Rabitz Types

| Specification | Detailed Description |

|---|---|

| Rabitz Material | Usually made from galvanized steel sheets to ensure resistance against moisture, corrosion, and deformation |

| Number of Ribs | Rib counts such as 9, 11, or 13 indicate mesh density; higher rib counts result in better quality and strength |

| Sheet Weight | Depends on rib count, sheet thickness, and mesh dimensions; typically ranges from 500 to 1100 grams |

| Standard Dimensions | The most common size is 60×240 cm, ideal for ceilings and walls |

| Main Application | Used for plaster substructures, suspended ceilings, vaulted structures, surface repairs, and improved mortar adhesion |

| Installation Method | Installed using binding wire, mesh tying, and direct attachment to metal or wooden substructures |

Conclusion

Rabitz, as one of the most important substructure materials, plays a key role in the final quality of plastering, cement works, and suspended ceiling execution. Proper selection depends on three parameters: rib count, weight, and mesh size. When these criteria are correctly understood, purchasing rabitz becomes easier and helps prevent execution problems and additional costs.

Ultimately, if you plan to evaluate rabitz types based on weight and rib count, reviewing updated rabitz price tables can help you make a more accurate decision.

Frequently Asked Questions

What is rabitz mainly used for?

Rabitz is primarily used for plaster substructures, suspended ceilings, and improving mortar adhesion on various surfaces. Its mesh structure helps maintain surface integrity and prevents cracking.

Does the number of ribs affect rabitz quality?

Yes. Rib count is one of the most important quality factors. Higher rib counts increase mesh density, resulting in greater strength and higher load-bearing capacity. This is why thirteen-rib rabitz generally offers superior quality compared to lighter models.

Is galvanized rabitz better than regular rabitz?

Galvanized rabitz is usually a better choice because it offers much higher resistance to moisture and corrosion. In humid construction environments, galvanization significantly extends service life.

How is rabitz installed?

Rabitz is installed using binding wire and direct attachment to metal or wooden substructures. Installation must be done carefully to ensure uniform mesh placement and prevent movement during plastering