What Is Welded Mesh? Types of Welded Mesh and Its Applications in Construction

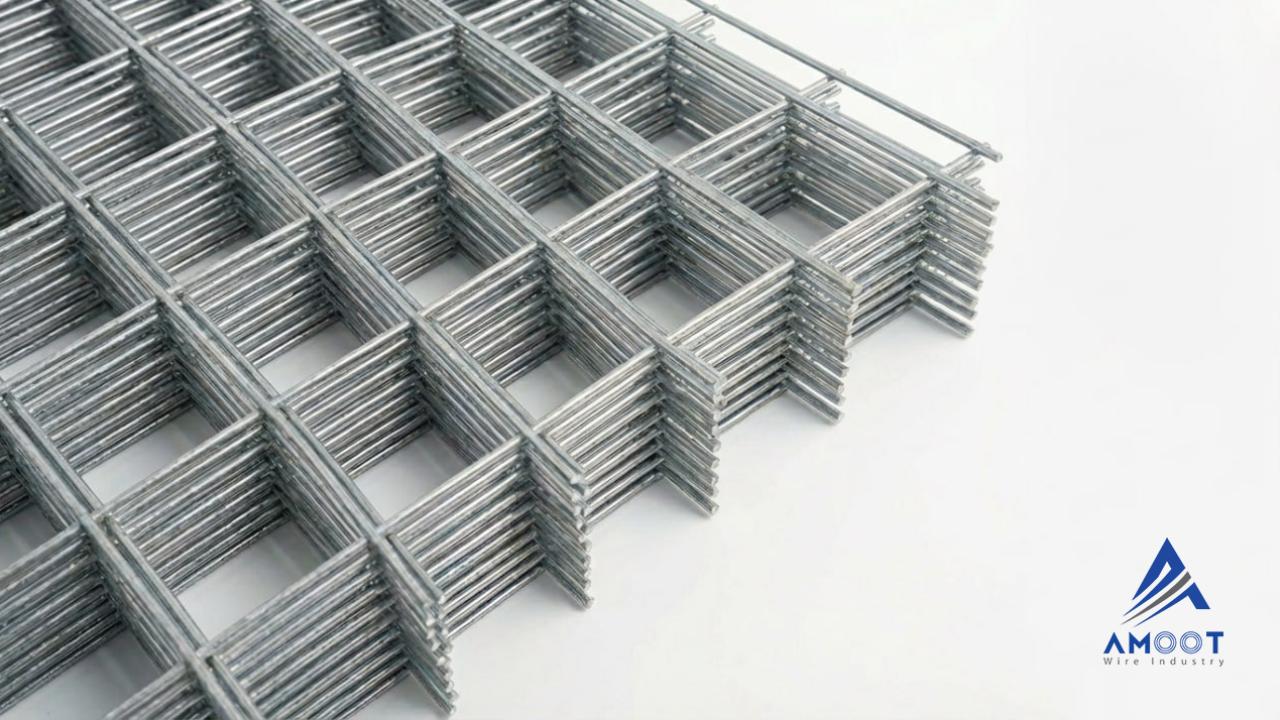

Welded mesh, or welded wire mesh, is one of the most popular and practical concrete reinforcement elements that in recent years has replaced a large portion of traditional rebar tying. This product is essentially a prefabricated steel grid in which the longitudinal and transverse wires intersect at 90 degrees and are connected to each other through resistance welding, also known as spot welding. The main reason behind the popularity of welded mesh is the very high execution speed and the uniform quality of welds—something that is not easily achievable with traditional tying using wire. In projects where execution time, dimensional accuracy, and minimization of human error are important, welded mesh is considered an ideal and economical choice.

Types of Welded Mesh Based on Rebar Type

To choose the right mesh, the first step is identifying the type of rebar. The difference between “plain mesh” and “ribbed mesh” directly affects strength, application, and price. In fact, the rebar type determines what type of loading the mesh is suitable for.

Plain Welded Mesh

Plain mesh is made from smooth wire or plain rebar, therefore it has a completely smooth surface without ribs. Due to this smooth surface, its friction with concrete is lower, but it is perfectly suitable and economical for industrial flooring, landscaping, parking lots, warehouses, and lighter projects. This type of mesh is usually produced in sizes 6 and 8 and has lower weight, which makes transportation and installation easier.

Ribbed Welded Mesh

This type is made from ribbed rebar. The ribs increase the bond with concrete and improve tensile and bending resistance. If the project includes foundations, load-bearing walls, composite slabs, or semi-heavy structures, ribbed mesh is the better and safer choice. This product is mostly produced using rebars sized 8 to 12 and is used in structures that need to withstand higher loads.

Technical Specifications of Welded Mesh

Understanding the technical specifications of mesh is essential for making a professional choice. Mesh is always defined by two numbers: rebar size and mesh opening size.

The mesh opening refers to the square-shaped grid cells and is one of the first things to consider when purchasing. Common mesh opening sizes in the Iranian market include 10×10, 15×15, 20×20, and 25×25 cm.

Where the opening is smaller, the number of rebars per square meter increases, which results in higher overall weight and higher product price. On the other hand, smaller openings increase panel strength and are ideal for heavy flooring or shotcrete applications.

Spot welds must be uniform, deep, and free from cracks. The quality of these welds is usually identified with a simple test: drop a sheet of mesh onto the ground with moderate force. If the welds crack or break, the product lacks sufficient quality.

Main Applications of Welded Mesh in the Construction Industry

Due to its execution speed and high strength, welded mesh plays an important role in many structural components. In composite slabs and metal deck slabs, it controls concrete cracking and distributes stresses uniformly. In industrial flooring—such as warehouses and parking structures—execution speed and uniform concrete thickness are crucial, and mesh fully meets these needs.

In shotcrete and tunnel construction, lighter meshes made from 2 to 4 mm wire are commonly used to hold sprayed concrete in place. Precast walls such as 3D panels cannot achieve sufficient strength without welded mesh applied on both sides. Additionally, in some lighter foundations, ribbed or heavy mesh is used to reduce rebar-tying time.

Difference Between Welded Mesh and Manual Rebar Tying

Welded mesh has several advantages over manual rebar tying, which is why many contractors prefer it. Manual tying is highly time-consuming and its quality depends entirely on the worker’s skill; but welded mesh is a factory-produced product with fixed dimensions and zero error.

Mesh is pre-manufactured and only needs to be laid and fixed on-site, so the installation speed is several times higher. Spot welds create connections far stronger than wire knots. Moreover, because dimensions are predetermined, material waste is almost zero. In high-volume or time-sensitive projects, choosing mesh is also more economical.

How to Calculate the Weight of Welded Mesh

Calculating the weight of welded mesh is very important for estimating the final cost. The weight of this product depends on three factors: rebar diameter, mesh opening size, and sheet dimensions. The exact calculation is somewhat complex, but there is a simpler approach.

In engineering calculations, the number of longitudinal and transverse rebars, the length of each wire, and the density of steel are considered. The weight of one sheet of mesh equals:

(Number of longitudinal wires × length of each wire × unit weight)

+

(Number of transverse wires × width of each wire × unit weight)

To simplify things, buyers usually refer to weight tables, one of which is provided below. This helps estimate the approximate weight per square meter based on rebar size and mesh opening.

Buyer’s Guide: What to Check Before Buying Welded Mesh?

When purchasing mesh, simply checking appearance or weight is not enough. Many manufacturers produce size 6 rebar with an actual diameter of 5.8 or even less. This reduces weight and significantly lowers mesh strength. Therefore, always verify the diameter tolerance.

Weld quality is another essential factor. Spot welds must be strong enough to resist bending or gentle impact without breaking. If the wires separate when lifting a sheet, the product is not suitable for concreting.

You should also watch out for rust. Black welded mesh may flake and lose strength if stored long-term in humid conditions. Finally, for projects where standard dimensions do not fit, custom mesh is recommended to minimize material waste.

Welded Mesh Weight Table Based on Rebar and Mesh Opening

| Rebar Size | Mesh Opening | Approximate Weight per m² |

|---|---|---|

| 6 Plain | 10×10 cm | ~3.5 kg |

| 6 Plain | 15×15 cm | ~2.5 kg |

| 8 Ribbed | 15×15 cm | ~3.8 kg |

| 8 Ribbed | 20×20 cm | ~2.9 kg |

| 10 Ribbed | 20×20 cm | ~4.5 kg |

(Values are approximate and may vary slightly depending on manufacturing tolerances.)

Conclusion

Welded mesh, due to its fast execution, network uniformity, proper strength, and consistent quality, has become one of the core components of the construction industry. By choosing the right rebar size and mesh opening and paying attention to weld quality, you can increase the useful life of the structure and avoid extra costs. If you need guidance in selecting the proper mesh size or checking daily prices, our specialists are ready to assist you.

Frequently Asked Questions

What are the standard dimensions of a mesh sheet?

The common size of mesh sheets in Iran is 2 meters wide and 6 meters long, though custom dimensions can also be produced.

What is the difference between light and heavy mesh?

Light mesh is typically made from 2 to 4 mm wire and is suitable for shotcrete, lightweight walls, or non-structural applications. Heavy mesh uses rebar size 8 and above and is suitable for foundations, slabs, and structural projects.

Can welded mesh be produced in custom dimensions?

Yes. Many manufacturers can produce non-standard mesh openings or custom sheet sizes, especially when the project volume is high.